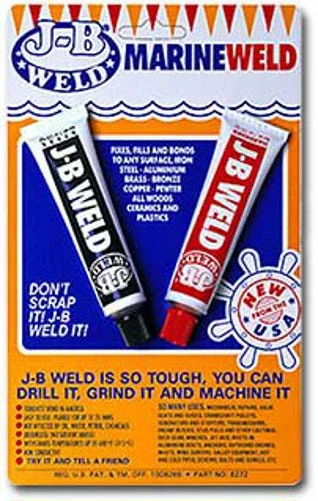

J.B. Weld JB Weld Marine Weld 8272 – Welding Tools & Accessories

$4.99 Original price was: $4.99.$3.79Current price is: $3.79.

- Worry-Free Shopping with Safe Payments

- Quality at its Finest

- Quality products for every lifestyle.

- Shop with confidence, enjoy free returns.

Formulated like our industrial-strength J-B WELD cold-weld, MARINE WELD cures as strong as steel, and is water- and weather-proof. It’s impervious to saltwater, chemicals, oil, acids, and other corrosive materials, and tolerates extreme temperature fluctuations. Every boat afloat should carry MARINE WELD for quick and permanent repairs from surf board nicks to hull repairs.

How Does J-B Weld Marine Weld Work?

MARINE WELD is packaged in two tubes. One contains liquid steel/epoxy resin, and the other contains hardener. When mixed together in equal portions, a chemical reaction occurs that turns the mixture into a compound as hard and tough as steel — and with similar properties.

MARINE WELD is so versatile that it’s even used by a marine science center to help mend the shells of sea turtles injured by boat propellers.

How to use J-B Weld Marine Weld

Use MARINE WELD as an adhesive, laminate, plug, filler, sealant, and electrical insulator. Squeeze out equal portions from the black and red tubes. Mix thoroughly. Clean surface to be bonded. Apply MARINE WELD, and let it cure. That’s all there is to it!

Like metal, MARINE WELD can be formed, drilled, ground, tapped, machined, filled, sanded, and painted. It stays pliable for about 30 minutes after mixing, sets in 4-6 hours, and cures fully in 15-24 hours. It’s water-proof; petroleum-, chemical-, and acid-resistent; resists shock, vibration, and extreme temperature fluctuations, and withstands temperatures up to 500° F. MARINE WELD is super strong, non-toxic, and safe to use. Before it sets, you can clean up with soap and water.

What Does J-B Weld Marine Weld Bond To?

Virtually any combination of iron, steel, copper, aluminum, brass, bronze, pewter, porcelain, ceramic, marble, glass, PVC & ABS, concrete, fiberglass, wood, fabric, paper — just about any porous and non-porous material.

| Shipping Weight | 1.000000 |

|---|---|

| Brand | J.B. Weld |

| SKU | 1590030 |

| Model Number | 8272 |

Be the first to review “J.B. Weld JB Weld Marine Weld 8272 – Welding Tools & Accessories” Cancel reply

Related products

Heaters, Furnaces & Fireplaces

Various Brands Wood Pellet Fuel, 40 lbs. – Fireplace Accessories

Caulk & Sealants

Quikrete Fine Play Sand, 0.5 Cubic Foot – 1113 – Cements Mortars

Paint Tools & Ladders

Various Brands Muriatic Acid Gallon – 12787 – Chemical Abrasives

Chain, Cable & Rope

Chain, Cable & Rope

Caulk & Sealants

Jetcoat All-Weather Pothole Patch, 50 lb. Bag 23753 – Coatings

Adhesives & Tape

Various Brands Electrical Tape 3/4″ x 60′ – 66042 – Adhesives & Tape

Benchtop & Stationary Tools

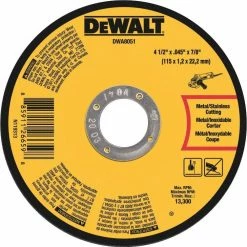

DeWalt 4 1/2 x .045 x 7/8″ Metal Cutting Wheel Type 1 DWA8051 – Benchtop Accessories

Reviews

There are no reviews yet.